Kraken зеркало рабочее официальный сайт

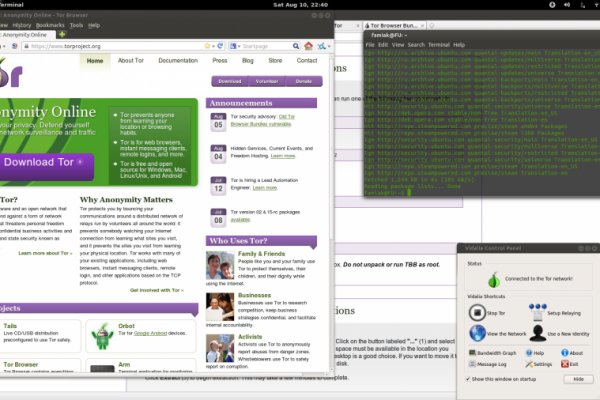

У этого термина существуют и другие значения, см. ОМГ.omg или «ОМГ» — крупнейший российский даркнет-рынок по торговле наркотиками, крупнейший в мире ресурс по объёму нелегальных операций с криптовалютой[3]. Существовал с 2015 по 2022 год[2][4][5].«ОМГ» была запущена в 2015 году, когда объединились Way Away и Legal RC, продававшие синтетические каннабиноиды и дизайнерские наркотики, отсутствовавшие на RAMP — ведущем даркнет-рынке[6]. Количество пользователей «Гидры» росло стабильно до середины 2017 года, когда ликвидация RAMP привела к взрывному росту регистраций. На середину 2019 года на ресурсе было зарегистрировано 2,5 миллиона аккаунтов, 393 тысячи из которых совершили хотя бы одну покупку. По оценке издания «Проект», за первую половину 2019 году на «Гидре» было заключено 850 тысяч сделок со средним чеком 4500 рублей[7]. По оценке «Лента.ру», в том же 2019 году за день устанавливалось более 13 тысяч закладок общей суммой 227 миллионов рублей[8].Кроме наркотиков, популярными товарами на «Гидре» являлись фальшивые деньги и документы, инструкции по противозаконной деятельности. Также на ресурсе реализовывались услуги, такие как сбыт наркотиков, интернет-безопасность и взлом аккаунтов. Кроме того, на «Гидре» выставлялись предложения по трудоустройству, как правило в сфере производства и сбыта наркотиков. В штат самой «Гидры» входили десятки людей, в том числе отдел рекламы, служба безопасности, химики и наркологи[7].Покупатели заходили на «Гидру» через Tor с луковой маршрутизацией. Они должны были зарегистрироваться и пополнять свой баланс, с которого средства (криптовалюта) списывалась продавцам (магазинам)[9]. Товар мог как находится в закладке к моменту оплаты, так и быть помещённым туда после. Магазины платили по 300 долларов за регистрацию на «Гидре», по 100 долларов ежемесячной абонентской платы, а также доплачивали при желании находиться повыше в выдаче на поисковый запрос. В течение суток после покупки клиент мог оставить отзыв о для товаре и продавце. При нарушениях магазин мог быть «Гидрой» оштрафован или закрыт. С каждой покупки «ОМГ» брала комиссию от 1,5 % (при сумме сделки больше 2 миллионов рублей) до 5 % (при сумме сделки меньше 200 тысяч)[7].В 2019 году «Лента.ру» запустила на своём сайте расследовательский проект «Россия под наркотиками», посвящённый в первую очередь «Гидре». В конце года проект стал лауреатом «Премии Рунета»[10]. Главный редактор «Лента.ру» Владимир Тодоров отвергал подозрения, что проект на самом деле являлся скрытой рекламой «Гидры»[11]. Сама «ОМГ» в меморандуме конца 2019 года заявила о рекламном характере проекта[12]. В том меморандуме платформа объявила о выходе на ICO, где 49 % «Гидры» собирались реализовать как 1,47 миллиона токенов стартовой ценой 100 долларов каждый[8]. Там же сообщалось о выходе 1 сентября 2020 года на международный рынок путём организации площадки Eternos, которая должна работать через специально созданную анонимную сеть AspaNET[13].По мнению президента Фонда имени Андрея Рылькова Анны Саранг, продолжительная и успешная, в сравнении с иностранными даркнет-рынками, работа «Гидры» обусловлена тем, что российские ведомства больше заинтересованы в создании видимости борьбы с наркоторговлей путём ареста её мелких членов[7].5 апреля 2022 Федеральное ведомство уголовной полиции Германии сообщило о ликвидации «Гидры» и конфискации биткоинов на сумму, примерно эквивалентную 23 миллионам евро[5].По данным Минюста США одним из владельцев сайта является 30-летний российский бизнесмен Дмитрий Павлов, при этом сам он отрицает какое-либо участие в деятельности «Гидры»[1].Примечания↑ 1 2 Минфин США назвал имя одного из организаторов даркнет-маркетплейса omg. Им оказался бизнесмен из Череповца . The Insider. Дата обращения: 8 апреля 2022.↑ 1 2 В Германии закрыли сервера даркнет‑маркета omg и конфисковали биткойны на 23 млн евро . Ведомости (5 апреля 2022). Дата обращения: 5 апреля 2022.↑ Россияне держат валюту в даркнете. Коммерсантъ↑ В Германии закрыли серверы крупнейшего в мире русскоязычного даркнет-рынка . РИА Новости (5 апреля 2022). Дата обращения: 5 апреля 2022.↑ 1 2 Кеффер, Лаура. В Германии закрыли серверы крупнейшего в мире русскоязычного даркнет-рынка omg Market . Коммерсантъ (5 апреля 2022). Дата обращения: 5 апреля 2022.↑ Россия под наркотиками. Проект Лента.ру↑ 1 2 3 4 Вся эта дурь. Исследование о том, на чем сидит Россия. Проект (издание)↑ 1 2 Что не так с ICO omg? Объясняет эксперт. Секрет фирмы↑ Сомик К. В., Хабибулин А. Г. Совершенствование противодействия экономической преступности, использующей возможности сети Интернет и криптографических средств // Теория государства и права, том 20, № 4, C. 220-232↑ В Москве вручили Премию Рунета-2019. Российская газета↑ Главред "Ленты.Ру" отверг обвинения в скрытой рекламе наркоплощадки omg. Инфо / 24↑ Лента, которая победила Гидру. DrugStat↑ Васильева Н. А. Анализ цифровых платформ в сфере незаконного оборота наркотиков для построения криминалистической характеристики данного вида преступлений // Юридический форум, сборник статей Международной научно-практической конференции. № 2, 2020. С. 71—76.СсылкиИсточник — https://ru.wikipedia.org/w/index.php?title=ОМГ_(даркнет-рынок)&oldid=121322914

Kraken зеркало рабочее официальный сайт - Где найти сайт кракен

� использования стороннего браузера, то стоит попробовать TunnelBear. Hydra больше нет! Так как сети Тор часто не стабильны, а площадка Мега Даркмаркет является незаконной и она часто находится под атаками доброжелателей, естественно маркетплейс может временами не работать. Таких людей никто не любит, руки бы им пообломать. Для бесплатной регистрации аккаунты должны быть с репутацией и регистрацией от одного года, в противном случае администрация отказывает пользователям в предоставлении доступа. Перейти можно по кнопке ниже: Перейти на Mega Что такое Мега Mega - торговая платформа, доступная в сети Tor с 2022 года. Org b Хостинг изображений, сайтов и прочего Хостинг изображений, сайтов и прочего matrixtxri745dfw. Onion - Acropolis некая зарубежная торговая площадочка, описания собственно и нет, пробуйте, отписывайтесь. Html верстка и анализ содержания сайта. Это не полный список кидал! Onion - torlinks, модерируемый каталог.onion-ссылок. Он действительно работает «из коробки» и открывает страницы, заблокированные любым известным способом, оповещая пользователя о входе на «запретную территорию» одним лишь изменением иконки на панели управления. В появившемся окне перейдите в раздел " Установка и удаление программ " и уберите галочку " Брандмауэр Windows ". Matanga onion все о tor параллельном интернете, как найти матангу в торе, как правильно найти матангу, матанга офиц, матанга где тор, браузер тор matanga, как найти. Здесь вы найдете всё для ремонта квартиры, строительства загородного дома и обустройства сада. Сайты сети TOR, поиск в darknet, сайты Tor. Таким образом, тёмный мир интернета изолируется от светлого. Ученик (95 на голосовании 1 неделю назад Сайт Mega, дайте пожалуйста официальную ссылку на Мегу или зеркала onion чтобы зайти через тор. И предварительно, перед осуществлением сделки можно прочесть. Onion - Dead Drop сервис для передачи шифрованных сообщений. Населен русскоязычным аноном после продажи сосача мэйлру.

Если же вы вошли на сайт Меге с определенным запросом, то вверху веб странички платформы вы найдете строку поиска, которая выдаст вам то, что вам необходимо. Валерий Владимирович super Евгений Ващейкин Отлично! 50gb облачного хранилища бесплатно. Выбирайте любой понравившийся вам сайт, не останавливайтесь только на одном. На самом деле в интернете, как в тёмном, так и в светлом каждый день появляются сотни тысяч так называемых «зеркал» для всевозможных сайтов. Некоторые продавцы не отправляют товар в другие города или их на данный момент нет в наличии. По скорости не уступает с Гугл драйв, наоборот выигрывает, особенно при скачке, Самое быстрая облако по моим тестам. Также многие используют XMR, считая ее самой безопасной и анонимной. Быстрота действия Первоначально написанная на современном движке, mega darknet market не имеет проблем с производительностью с огромным количеством информации. Форум Меге это же отличное место находить общие знакомства в совместных интересах, заводить, может быть, какие-то деловые связи. Спасибо огромное! Почему именно mega darknet market? В этом случае, в мире уже где-то ожидает вас выбранный клад. Не попадайтесь на их ссылки и всегда будете в безопасности. Vladimir Sosedov Я восхищен! Подборка Обменников BetaChange (Telegram) Перейти. После входа на площадку Hydra мы попадаем в мир разнообразия товаров. И это радует! Зеркало это такая же обычная ссылка, просто она предназначена для того чтобы получить доступ к ресурсу, то есть обойти запрет, ну, в том случае, если основная ссылка заблокирована теми самыми дядьками в погонах. Потребитель не всегда находит товар по причине того что он пожалел своих денег и приобрел товар у малоизвестного, не проверенного продавца, либо же, что не редко встречается, попросту был не внимательным при поиске своего клада. В том чтобы линки подменять и проксировать под расширением, не понимаю. Отзывы о великой Меге встречаются разные. Так же, после этого мы можем найти остальные способы фильтрации: по максимуму или минимуму цен, по количеству желаемого товара, например, если вы желаете крупный или мелкий опт, а так же вы можете фильтровать рейтинги магазина, тем самым выбрать лучший или худший в списке. Это больная тема в тёмном бизнесе. Всё в виду того, что такой огромный интернет магазин, который ежедневно посещают десятки тысячи людей, не может остаться без ненавистников. И самое главное плюс для меня это приложение для синхронизации в Линукс. Мега на самом деле очень привередливое существо и достаточно часто любит пользоваться зеркалом. Таких людей никто не любит, руки бы им пообломать. Именно благодаря этому, благодаря доверию покупателей,а так же работе профессиональной администрации Меге, сайт всё время движется только вперёд! Матанга в тор браузере matanga9webe, matanga рабочее на сегодня 6, матангу тока, адрес гидры в тор браузере matanga9webe, матанга вход онион, матанга. Переходник. Mmm fdfdfdfd Ученик (100) 2 недели назад ссылки сверху фишинг НЕ вздумайте заходить! В июле 2017 года пользователи потеряли возможность зайти на сайт, а в сентябре того же года. Как мы знаем "рынок не терпит пустоты" и в теневом интернет пространстве стали набирать популярность два других аналогичных сайта, которые уже существовали до закрытия Hydra. Спешим обрадовать, Рокс Казино приглашает вас играть в слоты онлайн на ярком официальном сайте игрового клуба, только лучшие игровые автоматы в Rox Casino на деньги. Сайты сети TOR, поиск в darknet, сайты Tor. Относительно стабилен. Заполните соответствующую форму и разгадайте хитрую капчу для входа в личный аккаунт: Чтобы проверочный код входа приобрёл более человеческий вид, потяните за голубой ползунок до тех пор пока не увидите знакомые символы. Наконец-то нашёл официальную страничку Mega. По типу (навигация. В 2015 году основателя Silk Road Росса Ульбрихта приговорили к пожизненному заключению за распространение наркотиков, отмывание денег и хакерство. Низкие цены, удобный поиск, широкая география полетов по всему миру. При этом они отображают нужную страницу с собственной шапкой и работают весьма медленно. Заходите через анонимный браузер TOR с включенным VPN. Кардинг / Хаккинг Кардинг / Хаккинг wwhclublci77vnbi. После входа на площадку Hydra мы попадаем в мир разнообразия товаров.